Head Actuator Of Hard disk drive

The actuator is the device used to position the head arms to different tracks on the surface of the platter (actually, to different cylinders, since all head arms are moved as a synchronous unit, so each arm moves to the same track number of its respective surface). The actuator is a very important part of the hard disk, because changing from track to track is the only operation on the hard disk that requires active movement: changing heads is an electronic function, and changing sectors involves waiting for the right sector number to spin around and come under the head (passive movement). Changing tracks means the heads must be shifted, and so making sure this movement can be done quickly and accurately is of paramount importance. This is especially so because physical motion is so slow compared to anything electronic–typically a factor of 1,000 times slower or more.

Head actuators come in two general varieties:

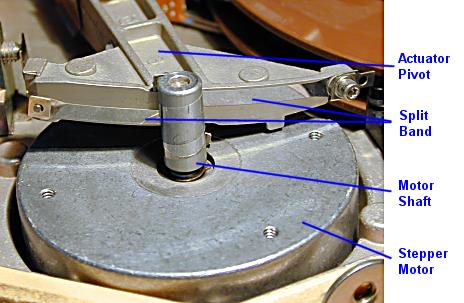

* Stepper Motors: Originally, hard disk drives used a stepper motor to control the movement of the heads over the surface of the platters. A regular motor turns in a rotary fashion continuously; it can stop at any point in its rotation as it spins around, kind of like the second hand on a wind-up wristwatch. A stepper motor can only stop at predefined “steps” as it turns around, much the way the second hand turns on an electronic, quartz wristwatch. A hard drive using a stepper motor for an actuator attaches the arms to the motor, and each time the motor steps one position clockwise or counterclockwise, the arms move in or out one position. Each position defines a track on the surface of the disk. Stepper motors are also commonly used for both turning the spindle and positioning the head on floppy disk drives. If you have a floppy drive, find one of its motors and turn it slowly with your hand; you will feel the discrete step-wise nature of its motion.

to the actuator arms. As the motor shaft turns, one half of this “split band” coils onto the shaft and the other half uncoils. When the motor turns in the opposite direction the process reverses. As this occurs the pivot moves

and in doing so, moves the actuator arms and the hard disk heads.

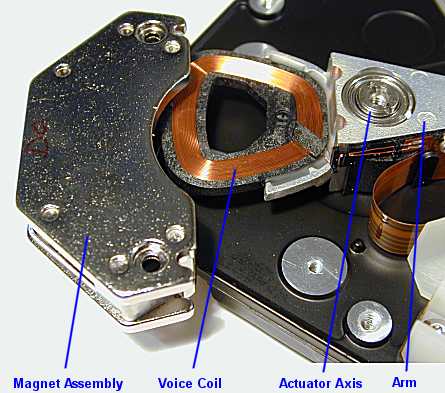

* Voice Coils: The actuator in a modern hard disk uses a device called a voice coil to move the head arms in and out over the surface of the platters, and a closed-loop feedback system called a servo system to dynamically position the heads directly over the data tracks. The voice coil works using electromagnetic attraction and repulsion. A coil is wrapped around a metal protrusion on the end of the set of head arms. This is mounted within an assembly containing a strong permanent magnet. When current is fed to the coil, an electromagnetic field is generated that causes the heads to move in one direction or the other based on attraction or repulsion relative to the permanent magnet. By controlling the current, the heads can be told to move in or out much more precisely than using a stepper motor. The name “voice coil” comes from the resemblance of this technology to that used to drive audio speakers, which are also basically electromagnets. All PC hard disk voice coil actuators are rotary, meaning that the actuator changes position by rotating on an axis.

A partially-disassembled voice coil actuator. The magnet assembly has been unscrewed from its mounting and pulled to the left to expose the coil. The magnet assembly consists of two metal plates (top one easily visible above, and part of the bottom one visible.) The magnet itself is mounted on the underside of the top plate, and spacers used between the plates to create the gap for the coil assembly. Being non-ferrous the coil moves freely between the plates, rotating the actuator on its axis as its magnetic polarity is changed. (Incidentally, the magnet is strong enough that after removing the spacers between the plates, the bottom plate got “stuck” on the magnet and required considerable effort to remove!)The primary distinction between the two designs is that the stepper motor is an absolute positioning system, while the voice coil is a relative positioning system. Commands given to a stepper motor actuator are generally of the form “Go in this direction to position A, where you’ll find item B”. Commands to a voice coil actuator are of the form “Go in this direction until you find item B”. Consider this analogy. In your backyard you have buried a “secret treasure” and want to tell a friend where to find it. When you buried it, you walked down a path 139 paces to the fourth oak tree, and buried it at the edge of the path. The stepper motor analog would be to tell your friend to walk 139 paces down the path, and start digging. The voice coil analog would be to tell him to look for the fourth oak tree and dig there. Obviously, using the “139 paces” method, your friend has a problem: his paces aren’t likely to be the same length as yours. In fact, even if you yourself walked out 139 paces twice, you’d probably end up in very different spots, since a “pace” isn’t an accurate or repeatable measure. On the other hand, the fourth oak tree will always be the fourth oak tree (barring disastrous chain-saw activity ).

Now hard disks of course don’t have to use inaccurate measures like “paces”, and it’s always the same stepper motor accessing the disk, not a “friend”, so why is saying “track #139” a big problem? For starters, motors change their characteristics over time, and after a year or two position #139 might not be where it was when the drive was first formatted. However, they have an even more serious problem: disk components (the platters and the head arms themselves especially) expand and contract with heat. Even if a stepper motor was perfect, it could not properly account for the fact that the disks are changing in size, and therefore, the tracks are literally moving around. If you consider our backyard analogy and think about what it would be like if the oak tree moved a few feet closer to or further from the house based on the day’s temperature, you start to realize how inadequate absolute positioning of this form can be.

A stepper motor has no way to compensate for expansion or contraction of the disk: all it can do is go to where “track #139” is supposed to be, and hope it finds it there! If it doesn’t find it because the motor and the disk have become out of sync, errors and data loss result. This is why older disks were so sensitive to temperature, and normally had to be low-level formatted periodically to make sure the tracks lined up with the heads properly. This is also why many drives would fail when first powered up after a weekend, but would work properly after the drive had been allowed to warm up.

The shortcomings of stepper motors were unfortunate but acceptable with old hard disks, because of their relatively low track density. To compensate, tracks could be written fairly wide so that the head would find them even if it was a bit misaligned. The first PC hard disks in 1982 had a track density of only two or three hundred tracks per inch (TPI). Even In 1986, the year Conner Peripherals introduced the first voice coil PC hard disk, density had increased to only about 1,000 TPI. Stepper motors are still used to drive floppy disks, for example, because the accuracy demands for floppies are much lower: a 1.44 MB floppy disk has a track density of 135 tracks per inch. In contrast, today’s hard disks have densities as high as 30,000 tracks per inch. With data packed this densely, tracks are extremely thin, and a stepper motor lacks the accuracy and stability necessary for proper operation.

All modern hard disks use voice coil actuators. The voice coil actuator is not only far more adaptable and insensitive to thermal issues, it is much faster and more reliable than a stepper motor. The actuator’s positioning is dynamic and is based on feedback from examining the actual position of the tracks. This closed-loop feedback system is also sometimes called a servo motor or servo positioning system and is commonly used in thousands of different applications where precise positioning is important. There are several different ways that the servo positioning system is implemented in PCs; the servo’s operation is discussed in its own section.

Data recovery Salon welcomes your comments and share with us your ideas, suggestions and experience. Data recovery salon is dedicated in sharing the most useful data recovery information with our users and only if you are good at data recovery or related knowledge, please kindly drop us an email and we will publish your article here. We need to make data recovery Salon to be the most professional and free data recovery E-book online.

World’s Top Data Recovery Hardware Tools

Easy to use at good price

Recover SATA, IDE, External HDDs, NVME SSDs, etc Order Now here

POTABLE DEVICE & NVME SSD RECOVERY TOOL

Recover USB Device and NVME SSDs at high speed! Read Details here.

DFL-PCIE DATA RECOVERY RECHARGE

Best data recovery hardware tool to start a data recovery business, read details here

RECOVER SCRATCHED HDDS

Recover lost data from scratched hard drives, read details here.

SURFACE PRO. RECOVERY

BEST HEAD REPLACEMENT TOOLS

The most cost-effective head replacement tools for Seagate, WD, Samsung, Hitachi, Toshiba, Fujitsu